Product Series

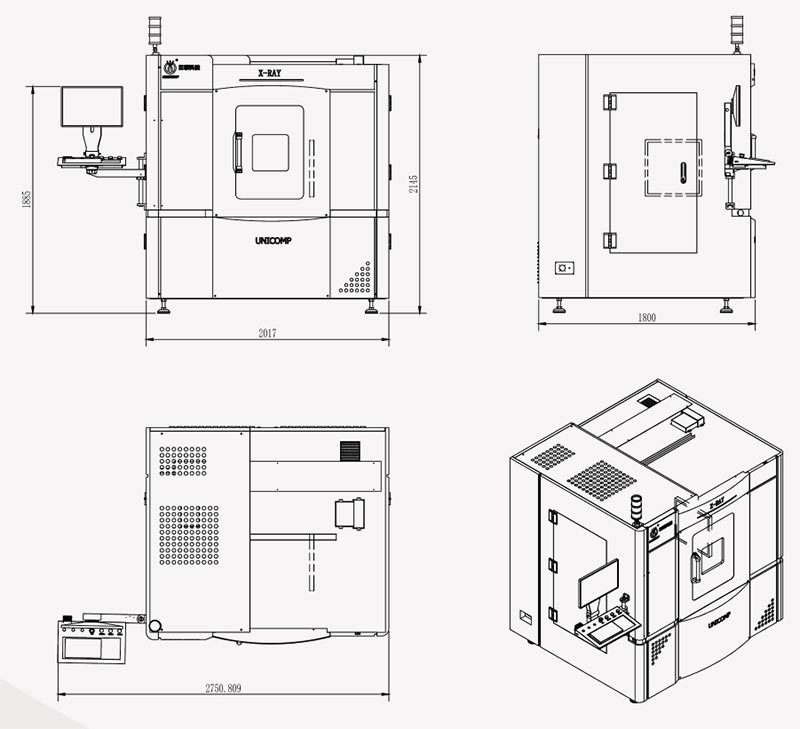

High-precision industrial CT inspection system UNCT2000

UNCT2000 is a high-precision compact industrial CT inspection system that can be used for various types.

Keyword:

Classification:

Industrial CT

Contact E-mail

Contact Phone

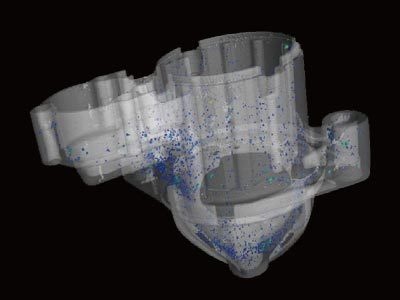

UNCT2000 is a high-precision compact industrial CT inspection system that can be used for various types, sizes, and materials, meeting the high-precision inspection needs of different industries. It is mainly applied to the inspection of small metal castings, non-ferrous metals, lithium battery new energy cell cores, chips, electronic devices, rock samples, cores, soil, fossils, composite materials, biological samples, and more.

|  |  |  |

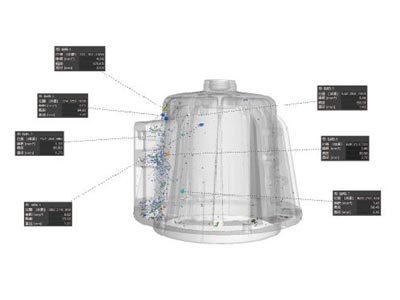

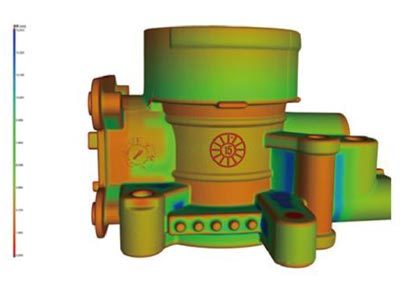

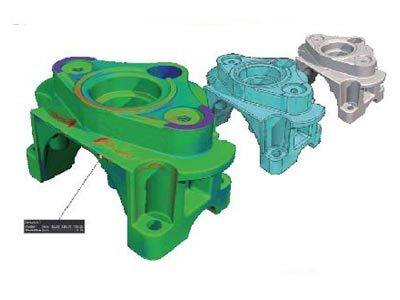

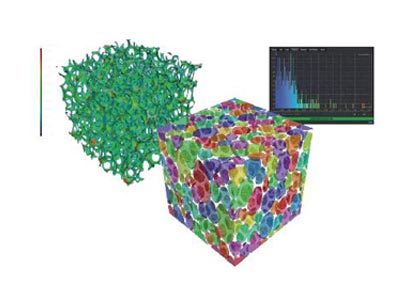

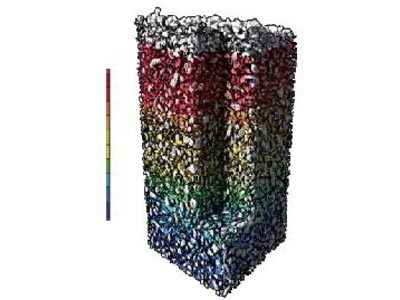

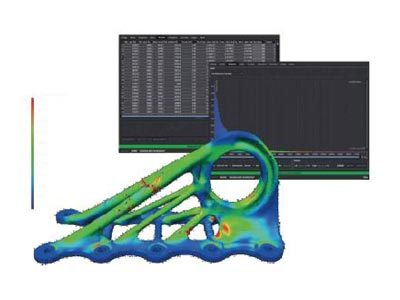

| Defect Detection | Wall Thickness Analysis | CAD Comparison | Measurement / Coordinate Measurement |

|  |  |  |

| Fiber Composite Material Analysis | Transmission Phenomenon | Structural Mechanics Simulation | Reverse Engineering |

|  |

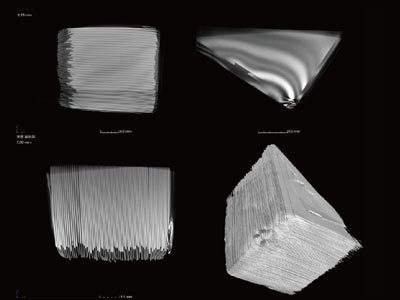

| Metal Casting Inspection Diagram | Lithium Battery New Energy Cell Inspection Diagram |

Equipment Features

1. Powerful Functions:

Equipped with both DR and CT dual imaging inspection functions;

It has three-dimensional scanning, data reconstruction, and analysis functions.

2. High Safety:

High-level protection, radiation levels far below national standards;

Equipped with multiple safety protection measures.

3. Simple Operation:

User-friendly designed control system, easy and convenient to operate, can be mastered proficiently after short-term training.

4. High Precision Inspection:

High-precision mechanical transmission system, advanced image processing and analysis software, inspection accuracy industry-leading;

Technical Parameters

| Overall Status | |||||

| Dimensions | 2635*2114*2069mm | Power Supply Voltage | 380AC/50Hz | ||

| Weight | Approximately 6000kg | Power | 9kW | ||

| Radiation Dose | <1 μSv/h | Operating Table | High Integration Integrated Operating Table | ||

| X-ray Tube | |||||

| Tube Type | Split Type | Focal Spot Size | <4 μm | ||

| Tube Voltage | 225kV | Tube Power | 320W | ||

| Imaging System | |||||

| Detector | Amorphous Silicon | Pixel Size | 139 μm | ||

| Effective Imaging Area | 427*427[mm] | Pixel Matrix | 3072*3072 | ||

| Motion Control System | |||||

| Maximum Detection Range | φ300×500 mm | Maximum Load Weight | 30KG | ||

| Software System | |||||

| Coordinate measurement module, design part/physical comparison module, wall thickness analysis module, porosity and inclusion analysis module, extended version porosity/inclusion analysis module, fiber composite material analysis module, extended version porosity/inclusion analysis module, manufacturing geometric correction module, volume mesh calculation module, structural mechanics simulation module, transmission field simulation module, and various other functions available. | |||||

*Note: The information in this manual only represents general descriptions and characteristics, and may change with technological advancements and equipment upgrades. Specific parameters are subject to the final agreement reached.

Video Show

Committed to providing reliable carbon fiber composite processing equipment solutions for global users

Please contact us to provide you with satisfactory products and become a reliable supplier and service provider in the industry.

One-stop service system

✔Customized Services✔After-sales service✔sustainable development✔Quality Assurance✔technological innovation

What makes Huayu Electromechanical so different from other suppliers?

Our advantage

Reliable quality, good reputation, price concessions, fast supply. Perfect service dedicated to the majority of users, so that customer satisfaction

Technical advantages

With an experienced R & D team, customized R & D continues to introduce new products. Introduce production equipment and processes to ensure stable product quality.

High cost performance

We can offer you more competitive and profitable prices. And we have reliable QA and QC team to ensure reliable product quality.

Perfect service

Perfect after-sales service system, to provide customers with all-weather technical support and maintenance services. Products are exported to the United States, Russia, Vietnam and more than 10 countries around the world.

Certificates

FAQ

Is export supported?

A complete after-sale service system provides customers with 24/7 technical support and repair services. Products are exported to more than 10 countries worldwide, including the United States, Russia, and Vietnam.

What are the characteristics of the types of carbon fiber prepregs?

Unidirectional reinforced carbon fiber prepreg: This prepreg is mainly composed of carbon fiber and resin matrix, characterized by the alignment of carbon fibers in one direction. This arrangement allows the material to exhibit excellent tensile strength and stiffness, making it particularly suitable for applications that need to withstand high tensile stress. Multidirectional reinforced carbon fiber prepreg: In contrast to unidirectional reinforcement, the carbon fibers in multidirectional reinforced carbon fiber prepreg are arranged in multiple directions. This arrangement provides better isotropy, meaning the material's performance is relatively balanced in all directions. Multidirectional reinforced prepreg is suitable for complex structures that need to withstand multi-directional stress, offering better overall performance and stability.

Can it be customized?

Support customized services, relying on an experienced R&D team, continuously launching new products through customized development. Introduce production equipment and processes to ensure stable product quality.

Need help? We're here to help!

To request a quote or find your local dealer, please complete the form below. If you cannot find the product you need.

Please feel free to contact us:+86-18753241699orhuayu_jd@126.comWe will get back to you within an hour.

Other Products